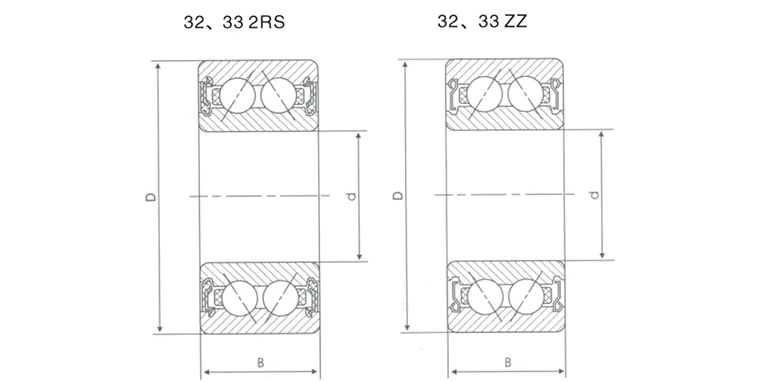

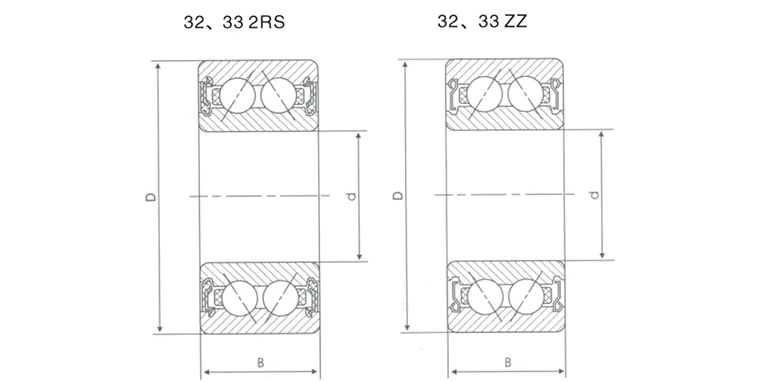

Basic composition

Inner and outer rings: precision machined tracks with grooves, usually made of high carbon chromium steel.

Double row balls: two rows of steel balls are arranged at a specific angle to achieve bidirectional load sharing.

Cage: nylon, brass or steel, to ensure uniform distribution of balls and reduce friction.

Contact angle (α): usually 15°, 25° or 40°, the larger the angle, the stronger the axial load capacity.

Differences from single row bearings

|

Features

|

Single row angular contact ball bearing

|

Double row angular contact ball bearing

|

|

Load direction

|

One-way axial + radial

|

Two-way axial + radial

|

|

Rigidity

|

Lower

|

Higher (double row support)

|

|

Installation complexity

|

Need to be used in pairs

|

Use independently to simplify assembly

|

2. Principle of high load-bearing capacity

- Mechanical advantages of double-row symmetrical layout

Radial load: Two rows of balls share radial force and reduce single-point stress concentration.

Axial load: The contact angle design decomposes the axial force into radial force, and the double-row structure can offset the thrust in both directions.

Torque load: The ability to resist overturning moment is significantly better than that of single-row bearings.

- Influence of key design parameters

Contact angle (α):

α=15°: Focus on radial load (such as pump equipment).

α=25°~40°: Focus on axial load (such as machine tool spindle).

Preload adjustment: Eliminate clearance by preload, improve rigidity but balance the risk of temperature rise.

- Material and process enhancement

Steel ball material: Ceramic ball (Si3N4) can reduce weight and withstand high temperature.

Groove polishing: Nano-scale surface treatment reduces friction loss.

3. Typical application scenarios

Machine tool spindle: High rigidity requirements under bidirectional cutting force.

Industrial robot joints: bear dynamic loads in multiple directions.

- Heavy load and high speed compatible scenarios

Gearbox: transmit radial force and axial thrust at the same time.

Centrifugal compressor: stability requirements under high-speed rotation.

4. Selection and use recommendations

Selection points

Load type: The axial/radial ratio determines the contact angle selection.

Speed limit: refer to the limit speed (dn value) in the bearing manual.

Lubrication method: grease lubrication (easy maintenance) or oil lubrication (high-speed scenario).

Common misunderstandings

Wrong preload: over-tightening causes temperature rise, and over-loosening causes vibration.

Mixed pairing: avoid mixing with single-row bearings to cause uneven force.

Maintenance key

Regularly check the clearance: the preload force may fail after wear.

Lubrication cycle: the grease change interval needs to be shortened in high temperature environment.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español