In heavy-duty machinery, the selection of bearings is crucial. They not only perform the tasks of rotation and support but also directly affect the stability, durability, and operating efficiency of the equipment. Among the many types of bearings, double row angular contact roller bearings have become the preferred component for heavy-duty machinery due to their unique structure and superior performance. They are particularly suitable for applications requiring high load capacity, axial forces, and radial forces, such as mining machinery, metallurgical equipment, and heavy transportation equipment.

So, why are double row angular contact roller bearings so important in heavy-duty machinery?

1. Working Principle of Double Row Angular Contact Roller Bearings

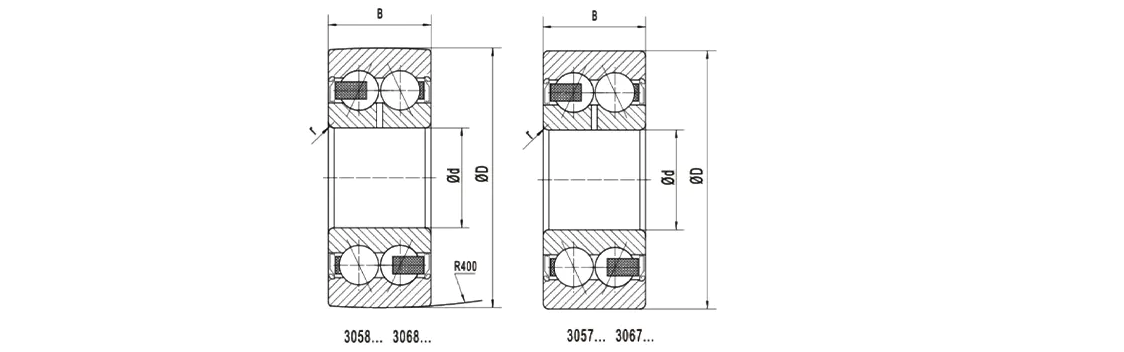

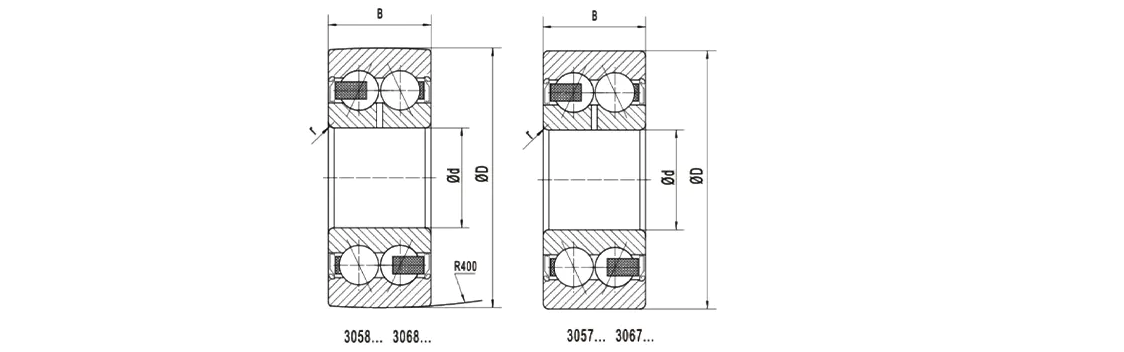

Double row angular contact roller bearings consist of two rows of rollers and an outer ring, usually designed in a double-row structure to provide higher load carrying capacity. Their working principle is similar to that of ordinary angular contact ball bearings, but compared to single-row bearings, the double-row design allows the roller bearings to simultaneously withstand axial loads from two directions and larger radial loads.

Angular Contact Design: The rollers of double row angular contact roller bearings are arranged at a certain angle between the inner and outer rings. This design allows the bearing to withstand higher axial loads. At the same time, the contact angle and arrangement of these rollers effectively distribute the axial load, ensuring stable operation.

Double Row Structure: The double-row design allows each row of rollers to bear a portion of the load, thereby increasing the load carrying capacity and the uniformity of load distribution, reducing the localized overload that may occur in single-row bearings.

This design allows double row angular contact roller bearings to effectively withstand axial forces in both directions while simultaneously bearing large radial forces, making them indispensable key components in heavy-duty applications.

2. Main Advantages of Double Row Angular Contact Roller Bearings

High Load Carrying Capacity

Due to their double-row design, double row angular contact roller bearings can distribute loads from various directions, greatly increasing their load carrying capacity. Especially under high load, high speed, and long-term operation conditions, they can maintain good working performance and stability. For example, heavy machinery such as cranes, mining equipment, and steel metallurgical equipment often need to withstand significant axial and radial forces, and double-row angular contact roller bearings provide an ideal solution.

Withstanding Axial and Radial Loads

Compared to other types of bearings, double-row angular contact roller bearings can simultaneously withstand axial and radial forces from two directions. For heavy-duty machinery, multi-directional loads are usually generated during operation. Single-row bearings are prone to deformation or damage under such heavy loads, while the double-row structure can better distribute these forces, thus improving the stability and reliability of the bearing.

High Temperature and High Pressure Resistance

The design of double-row angular contact roller bearings allows them to operate efficiently in harsh working environments. For example, in high-temperature and high-pressure environments such as metallurgy or mining, traditional ball bearings may fail to function properly due to excessive temperature or pressure, while double-row angular contact roller bearings can withstand these extreme conditions and maintain excellent performance.

Reduced Friction and Wear

Due to the rolling contact method used in roller bearings, the friction is greatly reduced compared to sliding bearings, resulting in less heat generation and a longer service life. In addition, the surface of the rollers and the inner and outer rings of the bearing are usually processed with precision technology, making the bearing run more smoothly and reducing the risk of friction and wear.

Suitable for High-Speed and Heavy-Load Working Environments

Double-row angular contact roller bearings are not only suitable for low-speed, high-load working environments, but also for high-speed machinery. Their excellent structural design ensures that the bearing can still withstand large loads even at high rotational speeds, thus providing superior performance in heavy-duty machinery requiring high speeds.

3. Application Fields of Double-Row Angular Contact Roller Bearings

Due to their excellent performance, double-row angular contact roller bearings are widely used in various heavy-duty machinery and equipment. The following are some common application areas:

Mining Machinery

Mining machinery often faces extreme working conditions, including high temperatures, heavy loads, and vibrations, therefore requiring reliable bearings to ensure stable operation. Double-row angular contact roller bearings can effectively withstand the large axial and radial forces in mining equipment, ensuring the reliability of the equipment during long-term operation.

Metallurgical Equipment

In the steel and metallurgical industry, equipment needs to withstand enormous loads and high-temperature environments. Double-row angular contact roller bearings can operate stably under these extreme conditions and are widely used in rolling mills, presses, and other heavy-duty metallurgical equipment.

Marine and Offshore Engineering

Ships and offshore platforms often need to operate for extended periods in humid, high-load environments. Due to their corrosion resistance and strong load-bearing capacity, double-row angular contact roller bearings are commonly used in critical components such as ship engines, steering gears, and offshore platforms.

Heavy Transport Equipment

Heavy transport equipment operating under high loads and harsh environments, such as excavators, cranes, and trucks, all require double-row angular contact roller bearings to ensure stable operation. These bearings effectively support the enormous loads generated during lifting, digging, and other operations.

Wind Power Generation Equipment

The rotating components of wind turbines need to withstand strong axial and radial forces, especially in high-wind environments. Double-row angular contact roller bearings are widely used in the main shafts and gearboxes of wind turbines, helping to maintain the efficient operation of the equipment.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español